SWR Pipes & Fittings

Soil, Waste & Rainwater Drainage Systems (Authorised Dealer Supply)

We supply high-quality Finolex SWR Pipes & Fittings designed for soil, waste and rainwater drainage applications in residential, commercial and institutional buildings.

As an authorised dealer, we ensure genuine SWR products that deliver reliable drainage performance, leak-proof joints and long service life.

Key Features of SWR Pipes & Fittings

- Designed for soil, waste & rainwater drainage

- Excellent chemical & corrosion resistance

- Smooth inner surface for efficient flow

- Strong & long-lasting performance

- Leak-proof joints with compatible fittings

Applications

- Soil & waste drainage systems

- Rainwater drainage

- Residential & commercial buildings

- Basement & underground drainage

- Sanitary drainage installations

Sizes, Joints & Standards

We supply SWR pipes and fittings manufactured as per applicable IS standards for drainage systems.

- Wide range of diameters available

- Compatible fittings for secure, leak-proof joints

- Designed for gravity drainage applications

Advantages

- Reliable drainage performance

- Low maintenance & long service life

- Resistant to soil gases & harsh conditions

- Easy installation with quality fittings

SWR Pipes

SWR Pipes with Integrated Rings

Conforming to IS 13592

SWR Selfit PVC Pipes

Conforming to IS 13592

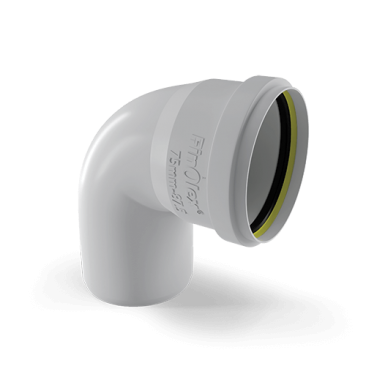

SELFIT FITTINGS

INTEGRATED RINGS FITTINGS

Technical Details

Jointing

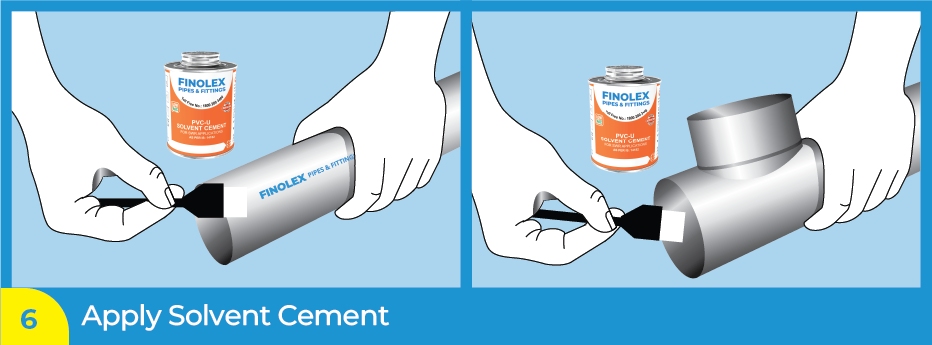

• For Selfit Pipes & Fittings:

1. Measuring: Measure the required length of pipe and mark.

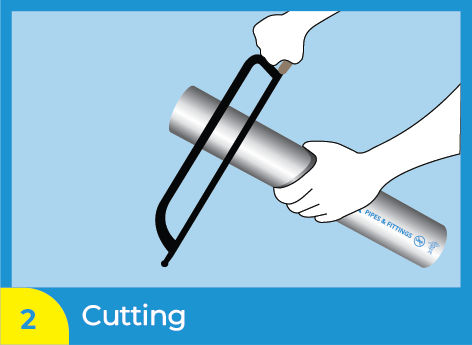

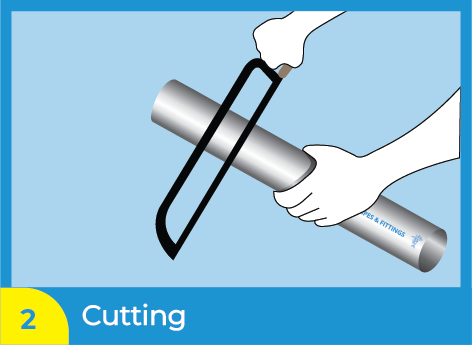

2. Cutting: Cut the pipe square. Angled cuts may cause leakage.

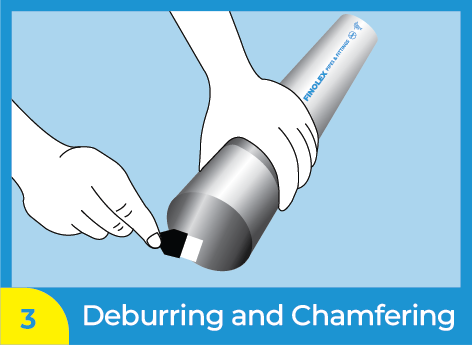

3. Deburring & Chamfering: Remove burrs and apply 10°–15° chamfer.

4. Cleaning: Clean dirt, grease or moisture using dry cloth.

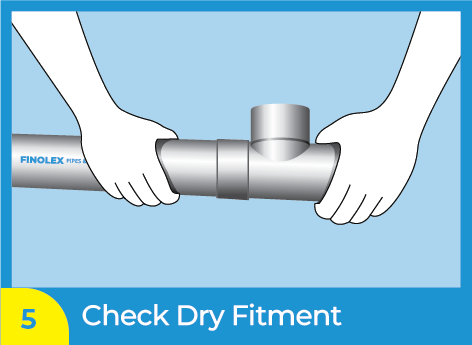

5. Check Dry Fit: Insert pipe one-third to half into socket.

6. Solvent Cement: Apply even cement layer on pipe and inside fitting.

7. Assembly: Join pipe fully and hold until it does not retract.

• For Pipes & Fittings with Integrated Rings:

1. Measuring: Measure and mark pipe length.

2. Cutting: Square cut required to avoid leakage.

3. Deburring & Chamfering: Remove burrs and chamfer pipe end.

4. Cleaning: Clean pipe surface thoroughly.

5. Check Dry Fit: Insert pipe partially to check fit.

6. Lubricant: Apply lubricant evenly on rubber ring.

7. Assembly: Push pipe fully into integrated ring socket.

Finolex Solvent Cement

PVC-U Solvent Cement for SWR applications.

| ml | 100 | 250 | 500 | 1000 |

|---|---|---|---|---|

| Container | Tin | Tin | Tin | Tin |

Rubber Lubricant

Finolex Rubber Lubricant is used for installation of SWR pipes and fittings with integrated rings.

| gms | 50 | 100 | 250 | 500 | 1000 |

|---|---|---|---|---|---|

| Container | Plastic Container | ||||

Approximate Joints per Litre

| OD (mm) | OD (inch) | Joints / Litre |

|---|---|---|

| 40 | 1¼” | 175 |

| 50 | 1½” | 130 |

| 63 | 2” | 125 |

| 75 | 2½” | 100 |

| 90 | 3” | 75 |

| 110 | 4” | 50 |

| 140 | 5” | 35 |

| 160 | 6” | 28 |

Why Buy From Us?

- Authorised Finolex Dealer

- 100% Genuine SWR Pipes & Fittings

- Competitive Dealer Pricing

- Bulk & Retail Supply

- Quick Local Delivery

- Product Selection Support

.png)

.png)